PLUTON's practice of using intelligent technologies for analysis of substation equipment state, as well as main data acquisition in a real-time mode

PLUTON in cooperation with "Schneider Electric Romania" carried out turn-key project that included design, development, supply and commissioning of two-unit modular traction substation on demand of "Oradea Transport Local S.A." (or simply OTL S.A.), the municipality-owned public transport company in Oradea (Romania).

Right from the very start of works PLUTON experts faced the necessity of meeting special design requirements. So, we had to consider that fact that future modular substation would be located under the limited space conditions, namely in the yard of a nine-storey building. Due to work of Design department we managed to place 2 modules of traction substation very compactly. We didn't interfere architectural complex on one side, and provided convenient access to modules equipment in case of needed operation and maintenance on the other side. Further, PLUTON used for the first time method of equipment arrangement that implied location of MV equipment and three transformers (two traction transformers and one auxiliaries transformer) in one module, and location of all DC equipment in other module.

Within the framework of the project the substation was equipped with reliable and modern rectifiers 750 V by PLUTON that meet European and international standards. They are manufactured with 12-pulse rectification circuit and have withdrawable design that provides free access to components and one-side maintenance with narrow front. Rectifiers were placed in a row with DC switchgears 750 V by PLUTON that provided easy maintenance, as well as equally important aesthetic appearance of equipment placed inside the module.

Due to compact size of DC switchgears and rectifiers (one section width equaled only 600 mm), we managed to minimize overall dimensions of substation modules.

Traction substation equipment included also MV cubicles SM6 20 kV by Schneider Electric. Active cubicle parts, namely load disconnector and earthing switch, are placed in a tube, filled with sulfur hexafluoride (SF6). Arc that appears while switching interrupts in this tube. Therefore, it provides increased load disconnector lifetime, as well as helps protect personnel against emergency situations. Significantly minimized size of cubicles is provided due to sulfur hexafluoride (SF6) insulation (in contrast to air-insulated cubicles that require much more space for their placement in modules).

Because of limited space for substation placement, as well as impossibility of building of foundation block for module installation and cable laying, PLUTON implemented for the first time the solution with cable cellar with access only from the inside of module. The cellar was designed as completely protected against moisture ingress and condensation due to application of cellar ventilation system. Cellar height is 1,5 m which provides convenient and quick maintenance of cable lines if required.

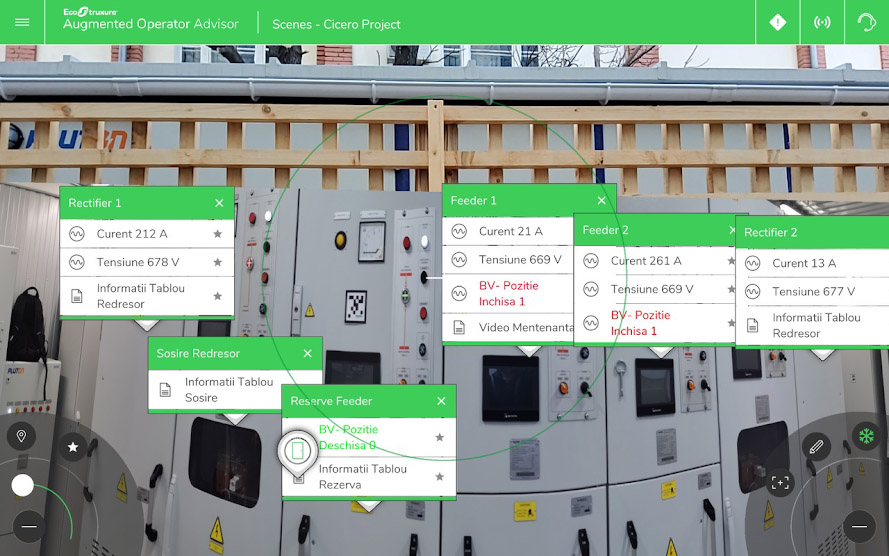

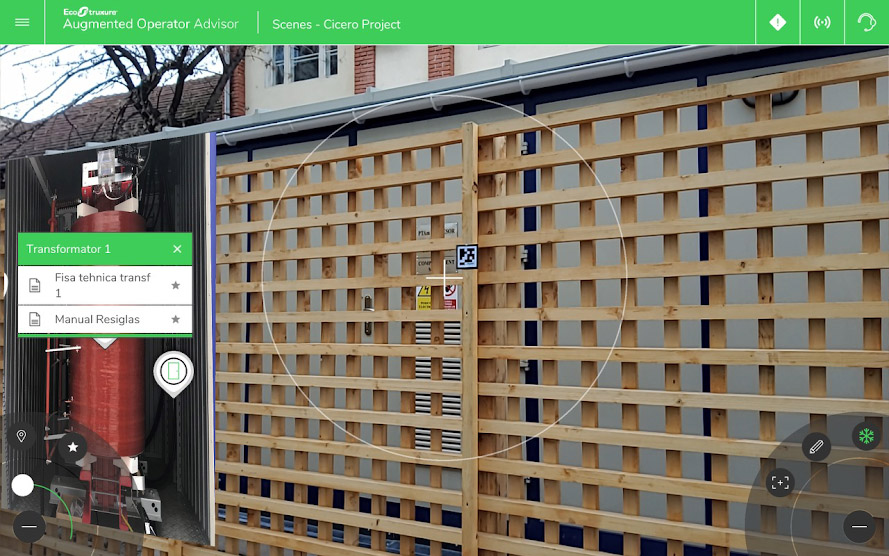

The distinguishing feature of the project was application of AR software by Schneider Electriс — EcoStruxure Augmented Operator Advisor for maximally deep and flexible state monitoring and substation equipment current parameters tracking. This program allows checking adjustments, analyzing state and reading of documents for any equipment in a real-time mode, as well as provides instant access to the required information for operators and technical experts. You should only point the camera of a tablet or a smartphone with the installed application at QR code of equipment, and EcoStruxure Augmented Operator Advisor will show the required data on its operation and current parameters at the display of the mobile device.

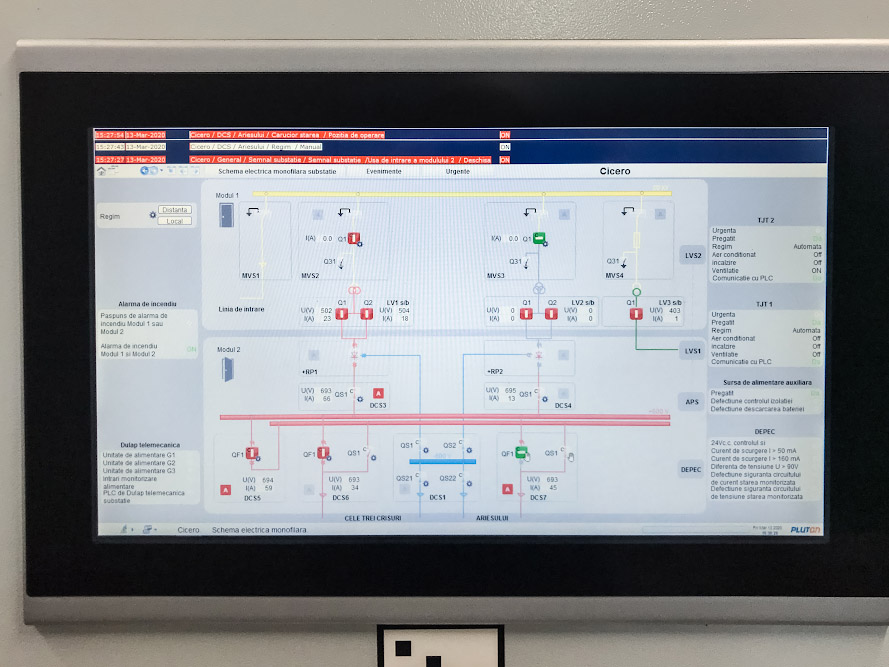

Control, monitoring and protection of substation equipment is carried out due to modern telecontrol cabinet, equipped with redundancy controllers that support data transfer protocol according to international standards IEC. Telecontrol cabinet included also power input, converting and distribution units, DC 24 V power supply units, panel computer with touch screen display, network equipment, controls and signaling equipment, as well as auxiliaries equipment.

Panel computer of telecontrol system is used as operator's automated workstation. It performs functions of control of substation power equipment state, as well as processing of received data, archiving of received and processed information, visualization of current information on mnemonic diagrams, generation of events report, including emergency events. Functions of substation main equipment telecontrol are also carried out from operator's automated workstation using special-purpose software. Telecontrol cabinet also contains equipment for connection to operator's control center via mobile or fiber-optics communication means.

PLUTON found the solution to the problem of overvoltage that appeared in traction network, by OTL S.A., as a result of excess power recovery by rolling stock. PLUTON experts developed and supplied overvoltage suppression unit, where suppression is provided by excess recovery power dissipation at load resistors installed at the substation.

Power supply of all systems with operating voltage is provided by auxiliaries system. Modular substation is equipped with lighting, ventilation, air conditioning, heating systems, as well as with fire alarm system.