Automatic control system of COILBOX intermediate backwind device

Coilbox technology is an intermediate process, aiming at high speed roll winding at the outlet from roughing mill group with further material uncoiling at a lower speed and its transfer to finishing mill group.

Coilbox technology made revolutionary changes in production of steel hot-rolled sheet due to two key principles: temperature keeping and long bars treatment. Coiling process decreases surface area of roll heat emission.

As a result, the bar after uncoiling has actually the same temperature as during coiling, allowing to carry out rolling in finishing mills with constant speed.

Automatic control system of intermediate backwind device (hereinafter IBD ACS) consists of 2 levels.

Lower automation level carries out data collection from technological sensors, electric drives, operator’s workstation controls and actuates electric drives, executive devices.

The second level is system of data automatic collection, its efficient display and storage, diagnostics, warnings and report documents formation. This level also carries out communication with hot rolling mill automatic control level via Ethernet network. The second level provides possibility of human participation in technological process, operational estimation, control, parameterization, events analysis within different time intervals and possibility of correct decision-making.

IBD ACS consists of the following main components:

- main master controller;

- electric drives controller;

- workstations №1, 2;

- HMI server;

- engineering station;

- drives diagnostics station.

Electric drives system is developed on the basis of AC electric drives. It includes 4 group and 8 individual electric drives. Reservation system on the basis of stand-by frequency converters and reserve switching cabinets is implemented for these electric drives. Stand-by switching is possible both in local mode and remotely by Coilbox operator. It minimizes downtime caused by possible frequency converter failure.

Thyristor starters are used for drives of hydraulic system pumps allowing to reach pumps nominal operation speed smoothly and shock-free.

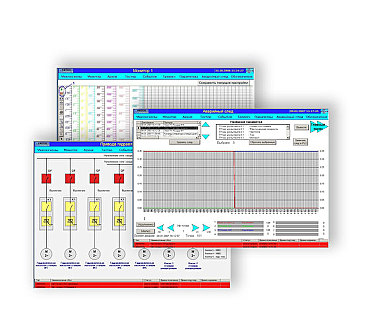

Human-machine interface software monitors different Coilbox systems current operation, displays for the operator data on system elements current condition, warning and emergency messages, provides archiving and emergency trace forming functions.

Human-machine interface software is developed for Coilbox workstations, electric drives diagnostics station and consists of the following main elements:

- main window — mnemonic diagram, that displays coiling and uncoiling process, as well as Coilbox mechanisms condition;

- mnemonic diagrams windows with electric drives system units displaying;

- settings windows;

- calibration windows;

- signals archive;

- list of events;

- list of active warning and alarm messages;

- archive of warning and alarm messages;

- monitoring;

- windows for greasing and water cooling systems condition displaying;

- windows for hydraulic system condition displaying.

Applied solutions for human-machine interface (HMI) organization provide Coilbox operator and servicing personnel with powerful and convenient tools for operational estimation of situation in Coilbox and hot rolling mill for prompt and efficient response to these situations.

Documents

All documentsHow can we help you?

Please contact us in case you have any technical queries, requests regarding customized procurement or delivery time of equipment.