Sites

MPK-Łódź operation control center

Works performed

- reconstruction design;

- HMI design development;

- supply of equipment: power cabinet, server cabinet, 4x3 video wall, automated workstations;

- SCADA software development;

- installation and commissioning works.

As part of this project, PLUTON implemented the latest automated operation control system currently allowing to control the operation of more than 30 traction tram substations in the city of Lodz and its suburb - the city of Zgezh.

The operation control center is the center of tram networks power supply control. And this is the place where all data from all the substations is received. The previous operation control center needed modernization, as it could no longer receive the scope of data that gradually increased due to implementation of new facilities. In a certain way, it also made the operator's work more difficult. The main goal of the Customer in this project was to keep up with the times and have reserves for the future. That is why the control center was rebuilt with complete replacement of equipment, including:

- primary and backup data servers;

- primary and backup automated workstation (AWS);

- video server;

- video wall;

- time server;

- network equipment;

- uninterruptible power sources.

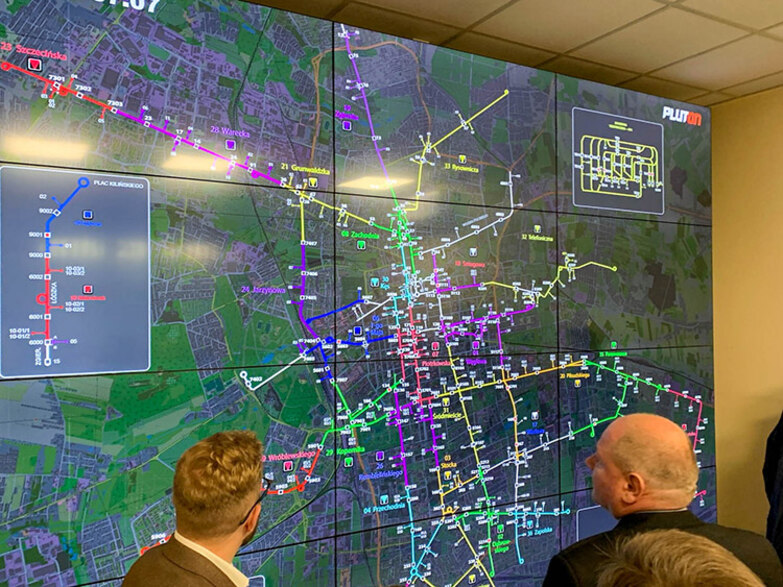

The key element of operation control center is the video wall - a screen for collective use, where the tram line power contact network diagram is displayed. The video wall is based on 12 video panels with 55 inches diagonal in 4x3 configuration. The innovative solution is to draw contact network with all power points on the city map. Due to this, the operator can quickly determine the location of mnemonic diagram elements on the city map using only the video wall, without spending time searching for information in documents, as was before.

The operation control center is equipped with time server being a constant source of accurate time due to synchronization via satellites. This makes it possible to obtain the exact real time of this or that event in the operation control center and at all the substations, and thereby simplifies the analysis of received data and emergency events. A 5G router is used to communicate with substation equipment via wireless channel.

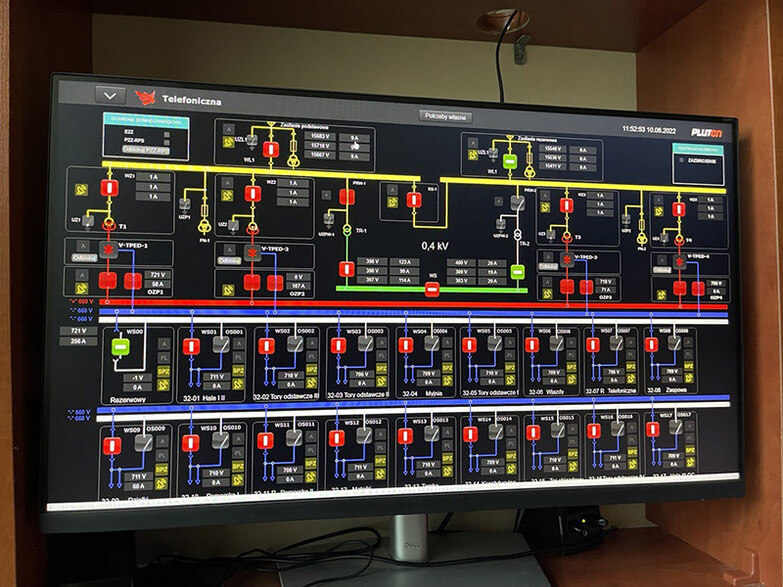

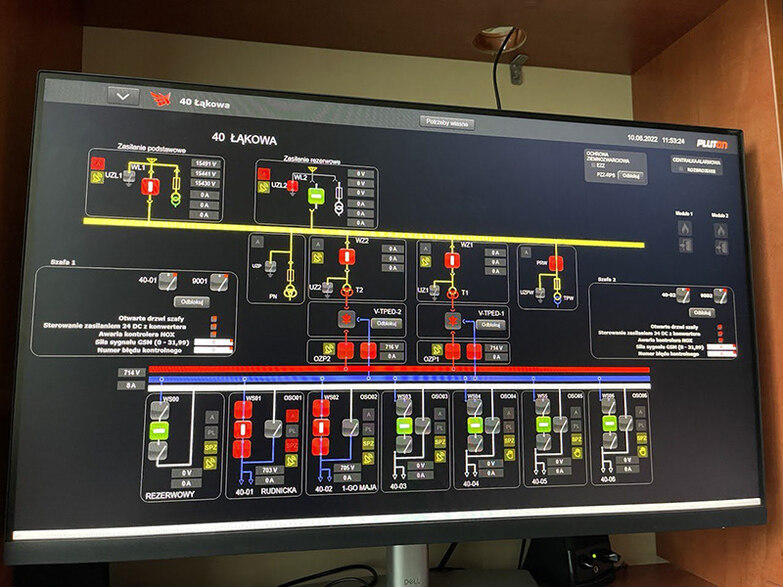

The operation control system is developed on the basis of SCADA Zenon COPA-DATA and performs the following functions:

- power supply operational control from the central operation control center;

- displaying and logging of technological control process progress - operation of technical means, diagnostics data and operative personnel actions;

- issuance of operational data on current and historical network parameters, state of switching equipment, technological parameters to the operating staff in a form convenient for work and analysis (mnemonics, tables, reports);

- collection and archiving of complete data on the equipment state in the logs of events and emergency situations for all the substations and specifically for each one;

- emergency and warning sound signaling of events;

- registration of all operator actions and the system status;

- circuit breakers and disconnectors control with the possibility of blocking them during the equipment repairs or being in reserve, and topological coloring of lines on the substations mnemonics according to the actual state;

- displaying of the uncontrolled equipment status in simulation mode on the video wall and substations mnemonics with recording of the changes state in the events logs;

- color displaying of the substations power supply areas on the city map, what allows fast switching;

- possibility of data exchanging with substations local telecontrol systems using modern international communication protocols.

Zenon software package includes:

- redundant server based on UNLMTD Zenon Supervisor license for an unlimited number of variables;

- operators AWS with client licenses;

- Historian archives maintenance modules;

- archived data saving on external machine;

- Automatic Line Coloring modules for automatic coloring of mnemonics lines;

- Modbus TCP, Modbus RTU data transmission drivers.

The automated operation control system is based on open architecture and is ready for scaling and expansion, and this makes it possible to connect new control facilities without stops and downtimes.

The entire system allows operators to react quickly in emergency situations, what means fast starting of alternative transport or rerouting the trams. It allows to keep passenger comfort at a high level.