AC electric drive KPPCH

AC electric drive KPPCH

PLUTON experts developed and introduced into production two modifications of traction regulated electric drive with asynchronous squirrel-cage motors based on frequency converters:

- frequency converter with separated rectifier and inverter units. A rectifier unit is installed indoors in a fixed position and provides DC power supply of trolleys (two trolleys, or one trolley and rail), which further provide a power supply of an inverter unit, installed directly on the moving object bogie;

- frequency converter with combined rectifier and inverter units installed on moving object bogie. A three-phase AC power supply is provided from three trolleys.

- FUNCTIONS AND STRUCTURE

- THREE-PHASE BRIDGE RECTIFIER VTM

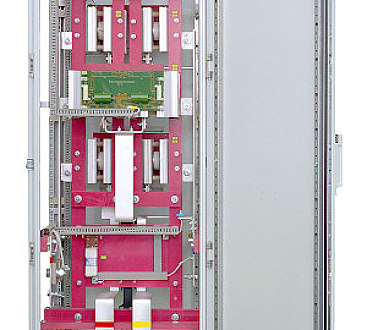

- CABINET WITH VOLTAGE INVERTERS SHIN

- CONTROL DESK PU

- BRAKING RESISTORS MODULES MTR

AC electric drive, type KPPCH, is provided for power supply, control, protection and diagnostics of traction drive with squirrel-cage asynchronous electric motors, e.g. bogie car pusher drive, which supplies from 1 up to 60 cars for unloading onto car dumper.

For example, for a car pusher drive we can apply two three-phase asynchronous motors, both with a capacity of 30...315 kW, with the squirrel-cage rotor. Each motor motions a separate wheel pair.

Pusher drive operation mode is intermittent with frequent start and braking, with motion direction reversing, thereby providing smooth start and braking.

Since pusher is supplied via two trolleys, AC drive KPPCH includes two main functional devices:

- three-phase bridge rectifier VTM;

- cabinet with voltage inverters SHIN;

Besides, KPPCH includes also control desk and braking resistors modules.

A three-phase bridge rectifier VTM cabinet is provided for ~380 V AC, 50 Hz converting into unregulated = 540 V DC for power supply of pusher voltage inverters via trolleys and current collectors.

Three-phase bridge rectifier VTM is a single-sided maintenance sheet steel cabinet with natural cooling that includes:

- input switchgears;

- current-limiting and decoupling devices;

- line filters, switching, and protection equipment;

- power semiconductor devices and their protection means;

- current and voltage measurement and indication devices.

Cabinet with voltage inverters SHIN consists of the following functional systems:

- traction drive control system;

- pusher auxiliaries circuits power supply system;

- cabinet microclimate monitoring and support system.

The traction drive control system consists of switching equipment and two voltage inverters. Traction voltage inverters are provided for pusher motors power supply, ensuring startup, braking, motors speed regulation, as well as motors current limitation.

Pusher auxiliaries circuits power supply system consists of auxiliaries inverter with a capacity of 5 kW; DC voltage supply = 220 V for power supply of brakes electromagnets; voltage supply ~220 V, 50 Hz, for power supply of compartment lighting fittings, as well as devices of visual and audio alarm during pusher movement.

Microclimate monitoring and support system of cabinet with voltage inverters SHIN consist of fan heaters, temperature regulators, and cooling unit. Fan heaters provide air heating inside the cabinet after a long stop at a temperature below 0 °C and support positive temperatures during the cabinet with voltage inverters SHIN operation.

The cooling unit supports temperature inside the cabinet not exceeding 35 °C by means of a built-in temperature regulator.

Control desk includes:

- AC drive KPPCH control system based on programmable logic controller;

- pusher indication elements and controls.

Control desk provides operator’s communication with electric drive system. Furthermore, the control system provides control, diagnostics, as well as information, warning, and alarm messages for the operator. Besides, operator malfunction protection, as well as archiving of various errors in electric drive operation is also provided. The Control system can be located in a separate cabinet upon the Customer’s request.

Braking resistors modules are provided for dissipation of energy accumulated in pusher and cars rotating masses, and ensure pusher braking mode with specified rate. Locomotive and cars stop time is up to 10 s. Braking resistors capacity is selected individually for each mechanism, depending on braking modes intensity and duration.

Technical parameters

Technical parameters of AC electric drive KPPCHDocuments

All documentsHow can we help you?

Please contact us in case you have any technical queries, requests regarding customized procurement or delivery time of equipment.