Ready-to-connect cabinet type frequency converters

Cabinet type frequency converters series VSI PN are converters with intermediate voltage circuit, made on IGBT-transistors with pulse-width modulation. They convert three-phase current system with constant frequency and amplitude to three-phase current system with variable frequency and voltage.

Such converters are used in fields, where three-phase current with variable frequency or power regeneration is needed. Drives rotation frequency is regulated smoothly and with low losses in wide range of motor mechanical characteristics due to application of digital control system, which operates both with and without speed sensor. Thereby PLUTON guarantees optimum coordination of converter and motor with machine tool with all the requirements to technological process. Both converter and asynchronous machine represent steady drive, which doesn't require regular maintenance.

Power range of frequency converters series VSI PN is from 1,5 up to 1500 kW, with voltage from 210 up to 690 V.

Benefits

- ready-to-connect converters resistant to short circuit, short circuit earth fault and no-load operation;

- cabinet execution with built-in power circuit breakers for direct network connection;

- implementation of single-motor and multi-motor synchronous and asynchronous drives;

- vector-oriented regulation;

- constant torque start;

- various regulation сircuits;

- selective clock frequency;

- stable without breakdown motor and generator operation mode;

- braking (option) with regenerator unit or chopper.

Application of digital electronics with microprocessor schemes, specially optimized for drives tasks, guarantees the required accuracy and reliability during control of any technological processes. Besides control and regulation, information electronics allows having convenient diagnostics, indication, messages, servicing and registration of errors and failures. Connection with other programmable controllers and digital systems of upper automation level is provided.

Benefits:

- wide range of rotation speed regulation without rotation speed sensor;

- high interference resistance due to application of LEDs and fiber-optic cables;

- sinusoidal input current, if necessary;

- manufacturing according to Customer's specific requirement with possibility of several converters installation in one cabinet;

- providing required protection level (IP);

- arrangement of control, monitoring and indication controls on cabinet door in the number specified by Customer;

- built-in machine du/dt or Sinus filter;

- input unit availability;

- wide range of options meets any requirements.

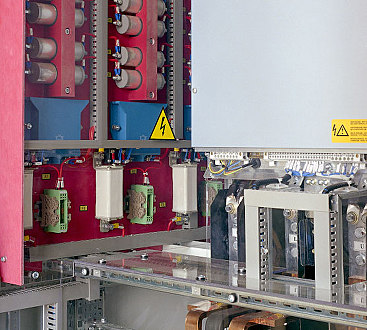

VSI-PN standard execution consists of built-in network current-limiting reactor, input circuit breaker or fused disconnector and network radio interference filter. Additionally, network and machine du/dt or sinus filters, braking chopper, microclimate control and support system, auxiliary power supplies, additional protection devices, process controllers, load disconnector, etc.

A wide range of optional accessories is available. Cabinet frequency converter can be designed according to Customer’s specific requirements.

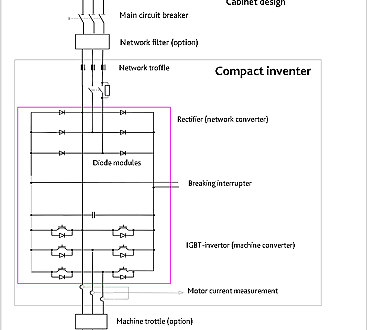

Frequency converters series VSI-PN consist of the following functional systems:

- power part;

- control, parameters monitoring and indication system;

- protections and limitations system;

- various auxiliary devices, needed for providing specific application requirements or Customer’s technical specification.

Power part consists of the following devices:

- network supply input;

- Schneider Electric compact frequency converter series ATV;

- machine du/dt (or Sinus) filter.

Control, parameters monitoring and indication circuit depending on specific requirements can be of different configuration, due to possibility of choosing from one of seven compact converter control programs.

Frequency converter software tools cyclically monitor possible fault sources. In case of fault an opening occurs, fault or opening cause information is displayed on connected control panel, on PC or on binary clamp.

There are critical faults that lead to immediate opening, and less critical ones that allow regulated opening with standard drive stop during opening. The fault is recorded in control system memory with data and time indication. The last 50 faults occurred on converter, are stored in memory and can be analyzed by maintenance personnel.

Protection functions:

- increased currents and short circuit protection;

- overheating protection;

- overload protection;

- phase failure protection at input and output;

- earth fault protection;

- protection against harmful supply voltage drop;

- underload (dry run, belt failure, reducer or coupling fault) protection;

- phase unbalance protection at input and output;

- motor temperature monitoring (upon request);

- insulation to earth monitoring (upon request);

- protection against undervoltage or overvoltage in intermediate circuit;

- internal auxiliary voltage monitoring.

Technical parameters

Technical parameters of VSI PN cabinet type frequency convertersDocuments

All documentsHow can we help you?

Please contact us in case you have any technical queries, requests regarding customized procurement or delivery time of equipment.